Semiconductor Diodes

Light Sources

Optical Accessories

Fiber Accessories

PhotoDetectors

Optical analysis device

Optical Imaging

Optomechanics

Applications

VCSEL Laser Diode

| 600-700nm VCSEL laser diode

| 700-750nm VCSEL laser diode

| 750-830nm VCSEL laser diode

| 830-870nm VCSEL laser diode

| 870-900nm VCSEL laser diode

| 900-1200nm VCSEL laser diode

| 1200-1350nm VCSEL laser diode

| 1350-1500nm VCSEL laser diode

| 1500-1600nm VCSEL laser diode

| 1600-1700nm VCSEL laser diode

Coherent Sources

| Single frequency laser

| Fiber coupled laser source

| Miniature laser module

| He-Ne laser

| Fiber laser

| Mid-IR laser Ready-to-use

| Mode-locked laser

| 1550nm NL single frequency laser

| Photon-light source association

| 532nm solid-state laser

| Semiconductor fab

| Mid infrared laser

| Solid-state laser

| Pump light source

Incoherent Sources

| Broadband Light Source/Illuminator

| Laser pumped phosphor broadband light source

| Erbium fiber ASE source

| Thulium fiber ASE source

| Ytterbium doped fiber ASE light source

| Dysprosium doped fiber ASE light source

| LED light source

| SLD light source

| Praseodymium doped fiber ASE light source

| Thermal IR light source

| He-Ne laser

Optical System

| Objective ,scanning & Tube lens

| Beam expander

| Camera lens

| Fly eye homogenizer

| Chromatic aberration correction

| LD Collimation & Focusing Tubes

| Galvanometer system

| Adaptive optics components

| Dispersion measurement system

| Single/multi-pass gas cells

| Photoacoustic spectroscopy

| Portable Raman Spectrometer

| Cage/Lens Tube Mounted Optics

| Shear interference

| Soleil Babinet compensator

| Integrated subsystem

Active devices

| EOM

| AOM

| High-speed transmitter/receiver

| Phase stabilizer

| Optical reference cavity

| Tunable narrowband Fabry Perot filter

| Liquid crystal tunable filter

| Spatial Light Modulator

| LCD products

| Birefringent system

| MEMS grating modulator

| Deformable mirror

| Adjustable focus lens

| Polarimeter

Optical Kits

| N-BK7 spherical lens set (installed)

| UV fused silica spherical lens set (installed)

| N-BK7 spherical lens set (not installed)

| Achromatic double laminated lens kit

| Aspherical lens kit

| Scattering film set

| ND filter kit

| Color filter kit

| Bandpass filter kit

| Hard-Coated Edgepass Filter Kits

| Precision Pinhole Kits

| Optical assembly kit

Fiber & patch cords

| Single-mode fiber

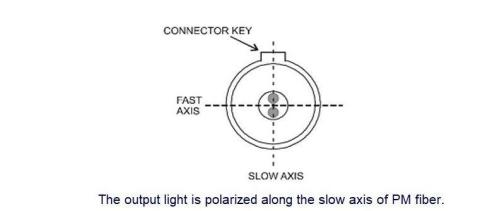

| PM single-mode fiber patch cord

| Multimode fiber bundle

| Custom fiber patch cord

| SM Fiber

| MM Fiber

| PM fiber

| Fluoride Fiber

| SM Polarization Fiber

| Rotating fiber

| High Non-Linear Fiber

| Double clad fiber

| Rare-earth doped fiber

| PCF fiber

| Coreless terminal fiber

| Fiber optic customization

| 2-in-1 PM patch cord

| SM Fiber Connector

| hollow fiber

| Multimode fiber jumper

| Metalized optical fiber

Fiber Optic Euipments

| Fiber optic table components &systems

| FiberPort collimator/coupler

| Fiber coupling platform

| Adjustable fiber coupler

| Optical fiber adapter

| L-Type Mating Tube

| Fiber optic compression block

| Fiber clamp with vacuum port

| Fiber head mounting bracket

| Collimator adapter

| FiberPort base

| Adjustable collimator adapter

| Mini collimator base

| MM Fiber filter cube, removable

| Cuvette holder

| MM Fiber filter mount, embedded

| 1x1 fiber rotary connector

| 1x2 fiber rotary splitter

| Rotary joint patch cord

Fiber optic components

| Fiber collimator

| Fiber coupler/splitter

| Fiber Optic WDM

| Circulator

| Fiber retroreflector

| Pump Combiner

| MM Fiber combiner

| Fiber polarization control component

| Fiber isolator

| Fiber attenuator

| Fiber optic filter

| UHV fiber feedthrough flange

| Optical fiber adapter

| Optical switch

| interferometer

| Patch Cord

| Fiber lab supplies

| Etalon

| Mode Field Adaptor

| optical delay line

| fiber optic phase modulator

Power and Energy Meters

| Photodiode Power Meter Sensors

| Thermal Optical Power Meter Sensor

| Thermal Position and Power Sensors

| Pyroelectric Energy Meter Sensors

| Digital handheld power meter sensors

| Multi-touch power meter probe sensors

| Analog handheld power meter

| Dual-channel power meter

| USB optical power meter

| Power meter kit

| Wireless power meter ,with sensor

| Miniature USB power meter

| Fiber power meter

| Power Meter Tutorial

| Integral ball

| Near-IR power meter

Imaging system

| Microscope System Overview

| Multiphoton Microscope

| Veneto inverted microscope

| Prelude imaging microscope

| Miniature two-photon microscope

| Multiphoton mesoscopic microscope

| OCT Imaging System

| Cerna Modular Microscope Platform

| Confocal system

| Birefringent microscope

| Birefringent system

| Microscope accessories

| Microscope software

| Tunable Ti:Sapphire femtosecond laser for multiphoton imaging

Imaging components

| Life Science & Microscope Optomechanics

| Microscope optical components

| Cerna wide-field & electrophysiological devices

| DIY confocal/laser scanning components

| High-speed modulators

| High speed modulator and attenuator

| Sample holder

| Microscope platform

| Light Sources

| Piezoelectric Microscope Objective Shifter

| Z-axis Piezoelectric Stage for Microscope Slides

| Microscope Vibration Isolation Table

| Laser scanning scope

Camera

| Microscope Camera selection guide

| CMOS microscope camera (1.6M pixels)

| MOS microscope camera (1.3-12.3M pixels)

| 5MP CMOS polarization camera

| SCMOS microscope camera (2.1M pixels)

| Camera, lens kit & Mounting base

| Camera terminology introduction

| Camera Noise Tutorial

| Customized/OEM Microscope Camera

| Camera software download

| UV camera

| Near infrared camera

| Mid infrared camera

| CMOS camera

Optogenetics

| Customized Optogenetic Solutions

| Overview of fiber optic photometry

| Optical fiber needle

| Needle implantation guide head

| Needle holder & adapter

| Optogenetic patch cord

| Rotating fiber optic patch cord

| 1x1 rotary connector

| 1x2 rotating fiber connector/splitter

| Interconnects and matching tubes

| Optogenetics driver kit

| Stainless steel & ceramic ferrules

| Optogenetics 2x2 couplers/beamsplitters

| MM Fiber filter cube, removable

| Fluorescent imaging filter kit

| Fiber coupled LED

| 473 nm fiber-coupled laser for optogenetics

Optical Mechanical Components

| Optical Posts Components

| Lens tube

| Adapter

| Mounting rack

| Cage system

| Mounting/Angle Bracket

| Optical guides

| Polaris ® Product Line

| Mini series opto-mechanical components

| Aperture

| Optical casing

| Vacuum components

| Instrument rack

| Optomechanical instruments

| Optomechanical equipment manufacturing

Spectroscopy

| Spectrometer and signal detector

| IRsweep spectrometer

| Photoacoustic Spectroscopy

| Broadband Sources & Spectral Lamp

| Single wavelength light sources

| Spectroscopy optical components

| Integrated subsystems for spectroscopy

| Pure air circulation device

| Spectroscopy sample container

| Multimode sample fiber bundles

| Transient absorption spectroscopy teaching kit

| Spectrometer teaching kit

| Complete incoherent light source product line

| Coherent light source product line

Quantum technology

| Single photon light source

| Single photon detection

| Single photon counting module

| Balance detector

| Diamond with NV center

| Polaris@Mount

| Piezoelectric interia vacuum displacement table

| Optical reference cavity with crystal film mirror

| Tunable Fabry Perot filter, narrowband pass

| Ready to use Ultra-low noise laser

| Vacuum components

| Sealed steam reference cell

| Quantum Optics Teaching Kit

| Quantum Erase Kit

| Quantum Encryption Suite

OEM/Manufacturing Capability

| OEM promotional brochure

| Customized/OEM scientific grade camera

| Desktop case production capacity

| Piezoelectric ceramic product production line

| OEM OCT system

| Semiconductor fab

| Fiber optic component manufacturing

| Elliptec technology for OEM

| Motion control equipment manufacturing

| OEM Photonics Services

| Anodizing production capacity

| Optical processing

| Optomechanical manufacturing processes

| Platform & breadboard manufacturing capability

| Optical fiber manufacturing